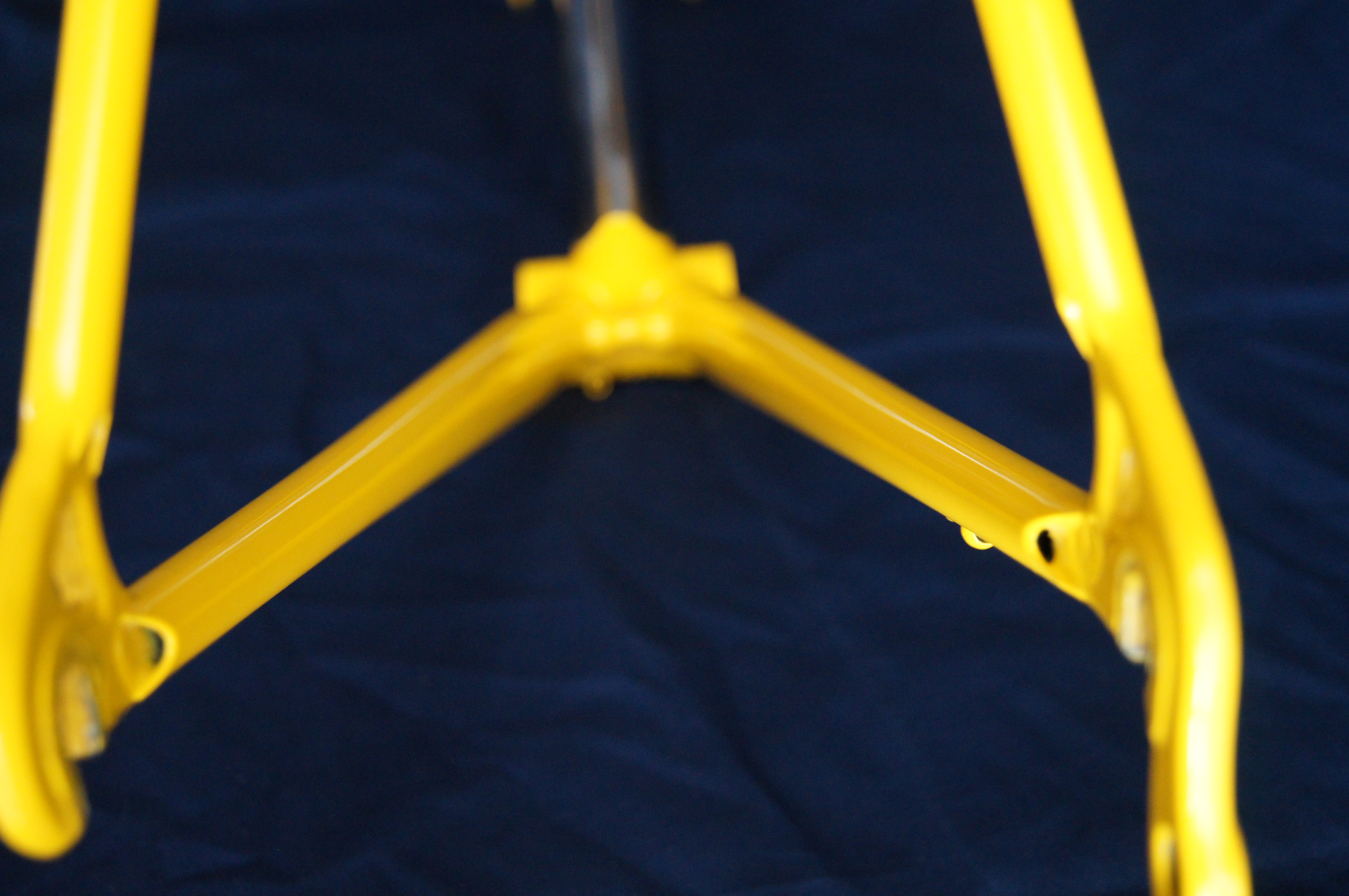

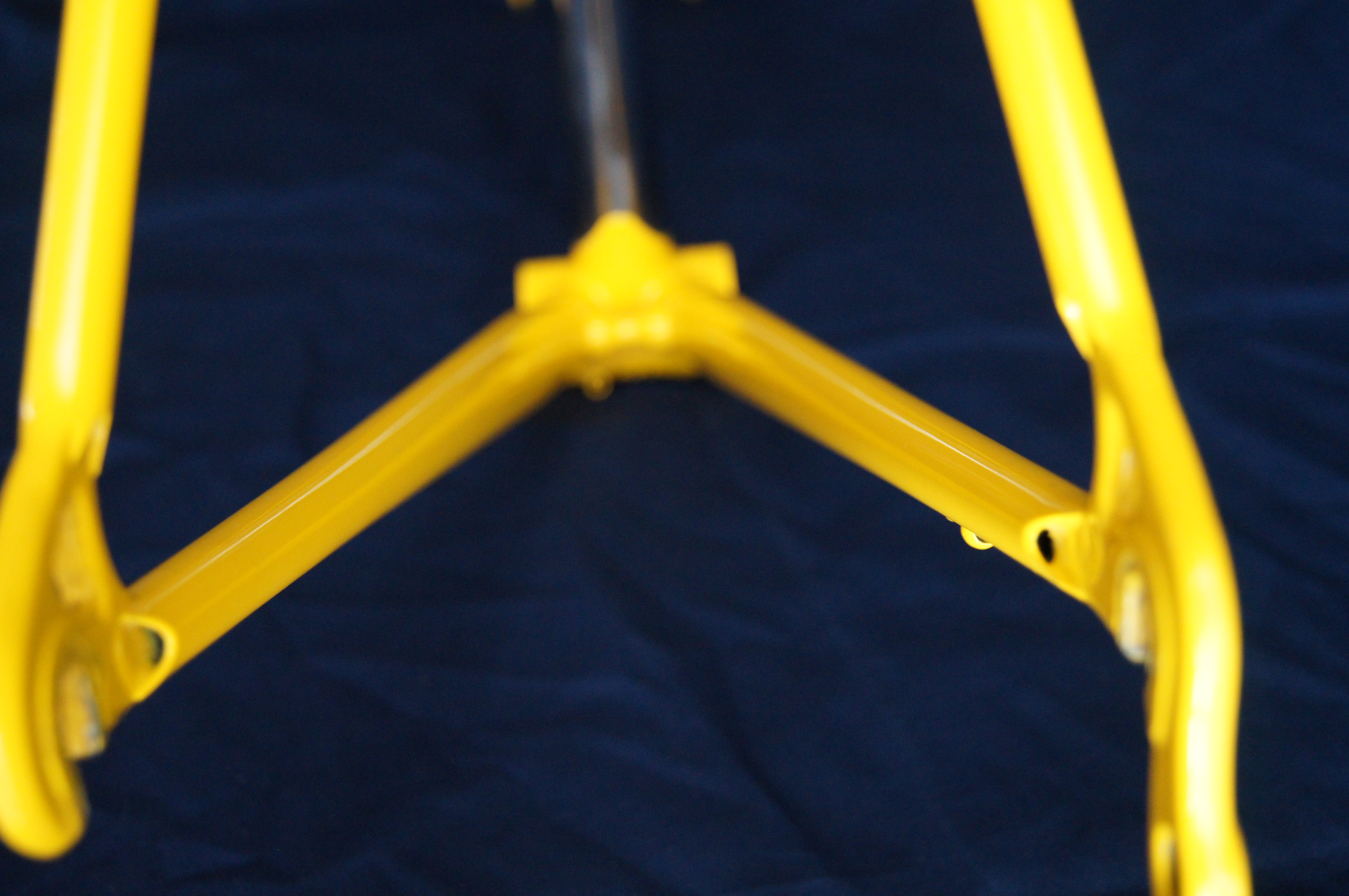

Zinc phosphate doing its job and rust free steel even after 16 years with last paint job. I was bummed as I was going to loose the zinc coating with this frames last paint job with a powder primer and the powder version of a zinc phosphate rust proofing.